Hacking Dynamics GP Perpetual Inventory

Background

It is a requirement that all inventory should be checked annually at a minimum. There is a further desire to ensure that inventory on the shelf reflects accurately that shown in Dyanamics GP inventory. Various factors can cause a mismatch so since inventory management was invented, stock checks are used to verify the quantities by physically counting the items in situe.

By stock counting items more frequently we are more likely to keep the levels in sync between the shelf and in the inventory module of GP.

GP Stock Take

GP has a stock count feature were it is possible to assign a stock count frequency (how many times a year we seek to count an item). The dates when the last and next stock counts were performed and are due is stored against each item, for each location.

A stock take in GP is simply a list of all the items we want to stock check. The user can use various criteria to select the attributes of items they want to put into this list. For the purposes of this discussion I am concentrating on using next count date as a basic for including items in the stock count. The user can select all items who next stock count due date is today or in the past (i.e. overdue).

Counting

When a stock take is started all the current inventory levels are snapshotted from inventory and updated against the items in the stock take list. The user then counts all the items putting next to the expected value from inventory, the actual quantity found by counting the item on the shelf.

An inventory transaction can then be built to correct the stock levels to those entered from the stock take.

The challenge

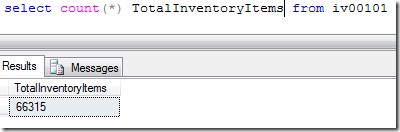

Setting the stock count intervals can become a challenge if you find a number of this sort of scale

Promoting a hands-off approach to system, what is needed is to default the information for stock takes.

SQL Help

It makes sense that the fastest turnover items should be counted more often as they are more likely to drift from the values held in GP. Most companies will classify items, there is an item class in GP that could be used to classify the different types of items or one of the user defined fields that are provided in GP.

A classic A,B,C,D code can be used for the frequency of item movements, stored in the user defined field.

A table can then be created that has the classification against the frequency that it should be checked. Lets call this table IV_STK_COUNT_INTERVAL.COUNTINTERVAL.

| Classification <br>(**REORDERCAT**) | Stock Check Frequency in working days <br>(**COUNTINTERVAL**) |

| --- | --- |

| A | 30 |

| B | 60 |

| C | 90 |

| D | 120 |

The stock count facility in GP has a calendar where working days can be defined, so all stock count activities are bound by working days.

For each item in the inventory sites table IV00102, there are three key fields of interest held against each item in each site;

| **NXTCNTDT** | Next count date |

| --- | --- |

| NXTCNTTM | Next count time |

| LSTCNTDT | Last count date |

| LSTCNTTM | Last count time |

| STCKCNTINTRVL | Stock count interval |

For the purposes of this example, ignore the time fields as that level of accuracy is not required.

Hence it can be seen that by updating a join between the classification stock check interval table created earlier and the inventory table, the stock take interval can be tied on a nightly basis to the classification of the product, so automating the maintenance of this field.

Discontinued items and items that have never had inventory

Discontinued items with no stock left can have stock take intervals set to zero, so they don’t get counted. The next stock count date should also be “zeroed” to 1900-01-01. The same applies to items that have never had stock.

UPDATE IV00102

SET STCKCNTINTRVL = 0,

NXTCNTDT = '1900-01-01',

NXTCNTTM = '00:00:00'

FROM iv00101

INNER JOIN

IV_STK_COUNT_INTERVAL

ON USCATVLS_6 = REORDERCAT

LEFT OUTER JOIN

IV00102

ON IV00101.ITEMNMBR = IV00102.ITEMNMBR

WHERE IV00102.LOCNCODE = 'MainWarehouse'

AND STCKCNTINTRVL != 0

AND IV00102.RCRDTYPE = 2

AND

(IV00101.ITEMTYPE = 2 -- discontinued

OR NOT (IV00102.BGNGQTY>0 OR IV00102.LRCPTQTY>0))

-- if has been no activity on this item ever

;

-- Next if the stock count interval is zero , set next stock

-- check to be 1/1/1900 so it don't come out on reports

UPDATE IV00102

SET NXTCNTDT = '1900-01-01',

NXTCNTTM = '00:00:00'

WHERE IV00102.LOCNCODE = 'MainWarehouse'

AND STCKCNTINTRVL = 0

AND NXTCNTDT != '1900-01-01'

AND IV00102.RCRDTYPE = 2;

Next Count Date

The next count date can be set by adding the stock take interval to the current date (taking into account non-working days). This is ok unless the creation of new products is lumpy in nature, in that case it is better to put some randomness into the interval to ensure the spread of products is better. Preventing no items to stock take one day and thousands the next!

In the script below, for the purposes of this article it has been simplified to not use a calendar table, instead it assumes a five day working week. This is part of a stored procedure called by SQL agent job nightly.

UPDATE IV00102

SET STCKCNTINTRVL =CASE WHEN iv00102.QTYONHND=0 THEN 0 ELSE IV_STK_COUNT_INTERVAL.COUNTINTERVAL END,

NXTCNTDT =

--stock interval for us does not include the weekends so add them on for this period for the date addidtion

dateadd(day, IV_STK_COUNT_INTERVAL.COUNTINTERVAL +

ROUND(((IV_STK_COUNT_INTERVAL.COUNTINTERVAL / 5) * 2), 0),

CASE WHEN LSTCNTDT='1900-01-01'THEN DATEADD(dd, 0, DATEDIFF(dd, 0, GETDATE())) ELSE LSTCNTDT END )

FROM iv00101

INNER JOIN

IV_STK_COUNT_INTERVAL

ON USCATVLS_6 = REORDERCAT

JOIN IV00102

ON IV00101.ITEMNMBR = IV00102.ITEMNMBR

WHERE IV00102.LOCNCODE = 'MainWarehouse'

AND CASE WHEN iv00102.QTYONHND=0 THEN 0 ELSE IV_STK_COUNT_INTERVAL.COUNTINTERVAL END != STCKCNTINTRVL

AND IV00102.RCRDTYPE = 2

AND IV00101.ITEMTYPE = 1

AND (IV00102.BGNGQTY>0 OR IV00102.LRCPTQTY>0)

Stock take

When in GP select the items to add to the stock take by choosing next stock take date as your criteria, selecting your location and choosing 2nd Jan 1900 to today’s date as the date range. This will capture all over due items and todays count items. You may find it useful to set up a reporting services report to show how many items are overdue, emailed daily as part of your KPI setup. This can be done by simply count records where nxtcntdt is not 1900-01-01 and less than today by site.

After Stock Take

When an item is processed as part of the stock take, the next date updated to the interval plus the current date. The last checked date is updated to that of the stock take. This does cause a problem with uneven distributions over time, hot dates can be created when too many items end up with similar dates to be checked. For this reason it is wise to create a report showing the distribution of items by date over a year, to anticipate and take action when peaks are identified. Run the report regularly as the distribution is in constant flux as the different intervals are applied and thrust forward the next check dates.

Set up

Evenly distribute the dates over the year, for the above reason, something relevant when seeding the dates for the first time too.

One more note is that a stock check should be performed by location on a regular basis too, in order to find items placed in wrong bins or items that are showing no stock where stock exists.

Summary

Reporting services scheduled reports

- Show number of items to count by date as distribution graph over year

- Show number of items overdue count for KPI purposes

Counts

- Count all the items due or over due a count

- Check all locations regularly for items misplaced

SQL

- Create regular job to align the stock take dates and frequency with the item class

- Use a levelling script to smooth out the dates should the distribution get too lumpy

--Over due stock checks

select NXTCNTDT as DueDate,count(*) as OutstandingPIChecks

FROM iv00102

where NXTCNTDT >'1900-01-01'

AND NXTCNTDT<getdate()

AND STCKCNTINTRVL>0

AND LOCNCODE='1'

GROUP BY NXTCNTDT

order by 1

--Stock Calendar Exception Days

select * FROM iv41001

-- Stock Calendar Setup

SELECT * FROM IV41000

--Show counts by week

--Uses helper table

--CREATE TABLE [CompanyCalendar](

-- [DateID] [datetime] NOT NULL,

-- [Day of Year] [smallint] NOT NULL,

-- [Day] [varchar](10) NOT NULL,

-- [Day of Week] [tinyint] NOT NULL,

-- [Day of Month] [tinyint] NOT NULL,

-- [Week] [tinyint] NOT NULL,

-- [Month] [tinyint] NOT NULL,

-- [Quarter] [tinyint] NOT NULL,

-- [Year] [smallint] NOT NULL,

-- [WeekDay] [bit] NOT NULL,

-- [Business_Day_Flag] [bit] NOT NULL,

-- CONSTRAINT [PK_CompanyCalendar] PRIMARY KEY CLUSTERED

--(

-- [DateID] ASC

--)WITH (PAD_INDEX = OFF, STATISTICS_NORECOMPUTE = OFF, IGNORE_DUP_KEY = OFF, ALLOW_ROW_LOCKS = ON, ALLOW_PAGE_LOCKS = ON, FILLFACTOR = 90) ON [PRIMARY]

--) ON [PRIMARY]

--GO

select [Week] CalendarWeek,count(*) as QtyPIChecks from iv00102

JOIN CompanyCalendar

ON NXTCNTDT=DateID

where NXTCNTDT >'1900-01-01'

AND STCKCNTINTRVL>0

AND LOCNCODE='1'

GROUP BY [Week]

order by 1